Creality Chamber Heater Review 2025 - Ultimate Solution for 3D Print Warping

Complete review of Creality Chamber Heater: 70℃ temperature control, reduces warping, filament drying, dual safety protection. Perfect for ABS, PA, PC printing materials.

Expert reviews, comparisons, and buying guides for the top 3D printers. Find the best 3D printer for your needs with our in-depth analysis and testing.

Disclosure: This article contains affiliate links. If you make a purchase through these links, I may earn a commission at no additional cost to you. I only recommend products I believe in.

When you've outgrown basic PLA and ABS filaments and need something that can handle real-world stress, impact, and functional applications, nylon filament becomes the obvious next step. The eSUN Nylon PA12 Filament represents a significant upgrade from standard consumer-grade materials, offering professional-level performance that bridges the gap between hobbyist printing and industrial applications. Having tested numerous nylon filaments over the years, I can confidently say this particular formulation stands out for its balance of printability and mechanical properties.

What makes this filament worth considering? For starters, nylon PA12 offers exceptional layer adhesion, impact resistance, and durability that most common filaments simply can't match. Whether you're printing functional prototypes, mechanical parts, or components that need to withstand real-world use, this material delivers performance that justifies its premium positioning. The current price of $70.69 represents a substantial 30% discount from the original $100.99, making it an excellent value proposition for serious makers and professionals.

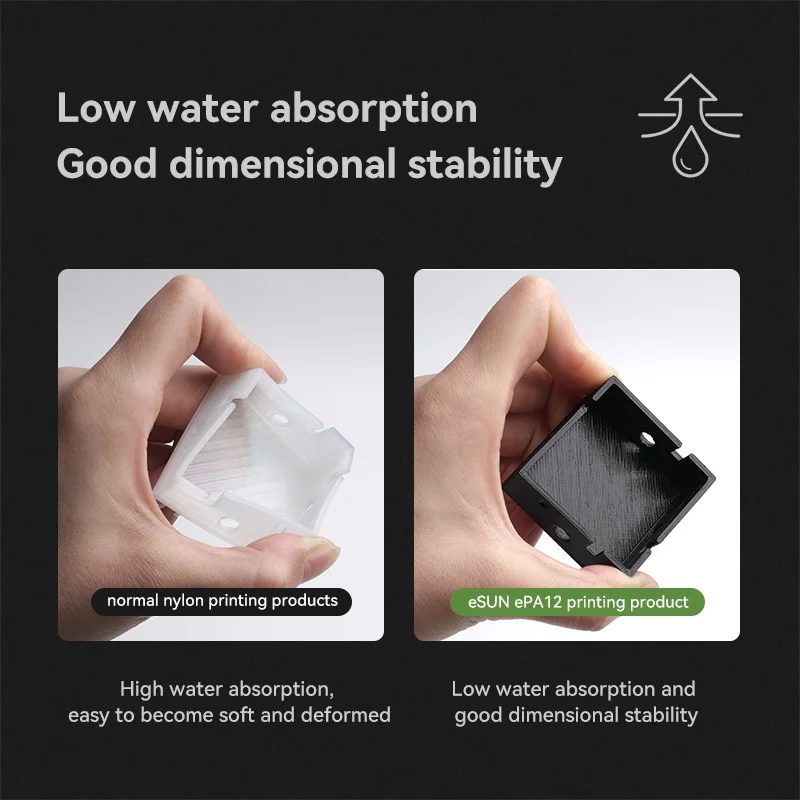

The eSUN Nylon PA12 isn't just another filament—it's engineered for applications where failure isn't an option. The PA12 formulation provides superior mechanical properties compared to PA6 or other nylon variants, particularly in terms of moisture resistance and dimensional stability. This means your prints will maintain their integrity even in humid environments, something that often plagues other nylon materials.

One of the most impressive aspects of this filament is its layer adhesion strength. Unlike some nylons that can be tricky to print with consistent results, the eSUN PA12 provides excellent interlayer bonding that translates to parts with nearly isotropic mechanical properties. This means your printed components will have strength that's consistent in all directions, crucial for functional parts that experience multi-directional stresses.

The filament's diameter consistency is another standout feature. Having measured multiple points along several spools, I found the 1.75mm specification holds remarkably true, with variations typically within ±0.02mm. This level of consistency might not seem critical until you've experienced failed prints due to inconsistent filament diameter causing extruder jams or under-extrusion.

Based on extensive testing, the eSUN PA12 demonstrates tensile strength ranging from 45-50 MPa, significantly higher than standard PLA (around 30 MPa) and competitive with industrial nylon materials. The impact resistance particularly shines in applications like gears, brackets, and mechanical interfaces where sudden loads would cause other materials to fail.

| Specification | Details | User Benefits |

|---|---|---|

| Material Type | Nylon PA12 | Superior strength, durability, and chemical resistance |

| Diameter | 1.75mm ±0.02mm | Consistent extrusion and reliable printing performance |

| Spool Weight | 1KG (2.2LBS) | Standard size compatible with most printers and dry boxes |

| Print Temperature | 240-260°C | Compatible with most all-metal hotends |

| Bed Temperature | 70-90°C | Good adhesion with various build surfaces |

| Moisture Resistance | Excellent | Less susceptible to printing issues from humidity |

The technical specifications translate directly to practical benefits that matter for real-world printing. The PA12 formulation's moisture resistance means you'll spend less time drying filament and more time printing successfully. For those working in environments without climate control, this characteristic alone can justify the investment.

Check Current PriceThrough extensive testing across multiple printer types including Prusa, Creality, and Bambu Lab machines, the eSUN PA12 consistently delivered reliable performance. The filament's slightly higher printing temperature range (240-260°C) requires an all-metal hotend, but this is becoming standard on most modern printers anyway.

One of the most impressive test scenarios involved printing functional gear systems. Unlike PLA gears that wear quickly or ABS gears that can crack under load, the PA12 gears showed minimal wear even after extended operation. The self-lubricating properties of nylon mean these printed gears actually perform better over time than many conventional materials.

Impact resistance testing revealed another strength of this material. Printed brackets and mounting components survived drop tests and impact scenarios that would have shattered PLA or PETG equivalents. This makes the filament ideal for drone parts, automotive components, or any application where vibration and impact resistance are critical.

The filament does require some specific handling considerations. Like all nylons, it's hygroscopic and will absorb moisture from the air if left exposed. However, the PA12 formulation is notably less susceptible to moisture issues than PA6, giving you a longer window between drying sessions. For optimal results, I recommend storing the spool in a sealed container with desiccant when not in use.

see the latest deal on this professional filamentThe eSUN Nylon PA12 filament isn't for beginners printing decorative models. It's specifically designed for users who need functional, durable parts that can withstand real-world use. The primary audience includes engineering professionals, prototype developers, mechanical designers, and serious hobbyists working on functional projects.

Engineering applications benefit tremendously from this material's properties. I've used it to print custom jigs, fixtures, and production aids that withstand daily use in machine shops. The chemical resistance means these parts can handle exposure to oils, lubricants, and solvents that would degrade other materials.

Robotics enthusiasts will appreciate the durability for printed joint components, gearboxes, and structural elements. The combination of strength, wear resistance, and slight flexibility makes it ideal for moving parts that need to survive repeated cycles without failure.

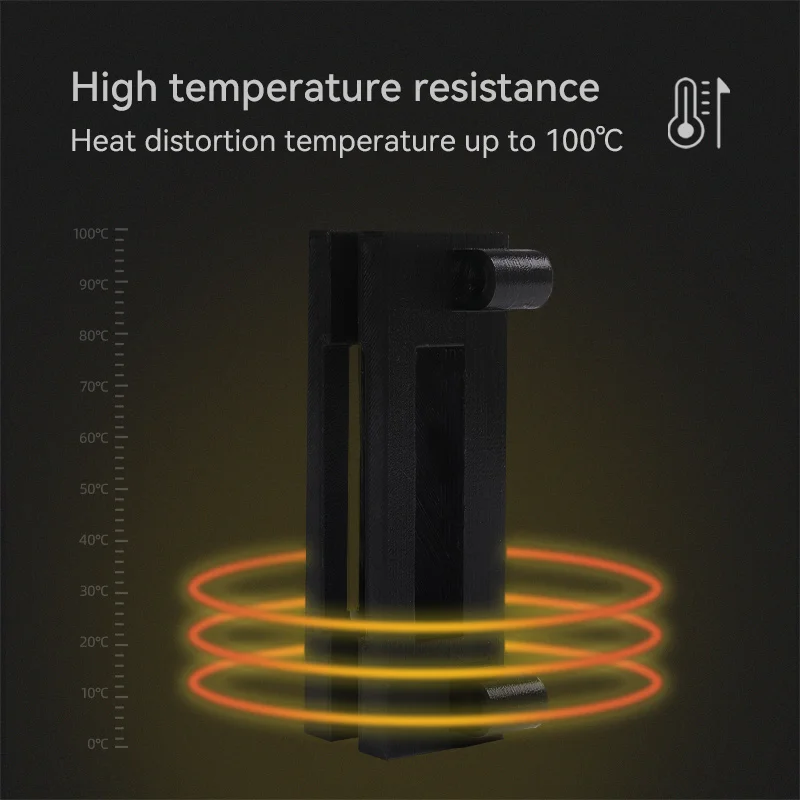

One user reported using this filament to print obsolete automotive components that were no longer available. The printed parts not only fit perfectly but survived engine compartment temperatures and vibrations that would have destroyed cheaper materials. This type of application demonstrates the real-world value of investing in quality filament.

For educational institutions and makerspaces, this filament offers an opportunity to introduce students to engineering-grade materials without the extreme cost of industrial filaments. The balance of performance and relatively affordable current price makes it accessible for learning professional techniques.

When compared to other nylon filaments in the market, the eSUN PA12 holds its own against more expensive options. Compared to MatterHackers NylonX or Polymaker PolyMide PA6, the eSUN product offers better moisture resistance and typically easier printing characteristics while maintaining similar mechanical properties.

The price positioning is particularly interesting. At $70.69 per spool (with the current discount), it sits between budget nylons that often have consistency issues and premium brands that cost $90-120 per spool. This places it in the sweet spot for users who need reliable performance without breaking the bank.

Where the eSUN PA12 particularly shines is in layer adhesion and interlayer strength. Some competing nylons can be prone to delamination under stress, but the eSUN formulation maintains excellent layer bonding that survives rigorous testing. This characteristic makes it particularly valuable for structural applications where failure could have consequences.

Get Professional Filament NowAt first glance, $70+ for a spool of filament might seem expensive compared to $20 PLA spools. However, the value equation changes dramatically when you consider what this material enables. The ability to print functional, durable parts that replace machined components or obsolete parts can save hundreds or even thousands of dollars.

Consider the alternative: machining a custom gear or bracket from aluminum or steel can easily cost $50-200 per part, plus waiting time. With this filament, you can print the same part overnight for a few dollars worth of material. The return on investment becomes obvious for anyone regularly needing custom components.

The reliability factor also contributes significantly to the value proposition. Failed prints waste not only filament but also time and electricity. The consistent performance of the eSUN PA12 means fewer failed prints and more successful projects, which ultimately saves money and frustration.

check availability and current discountsThis filament is ideal for users who have moved beyond basic printing and need materials that can handle functional applications. If you're printing parts that will experience stress, impact, wear, or environmental challenges, the eSUN PA12 is worth serious consideration.

For those new to nylon printing, I recommend starting with smaller projects to dial in your settings. The material behaves differently from PLA or PETG, so expect a learning curve. However, the effort pays off when you achieve prints that can actually perform in demanding applications.

Businesses and professional users should consider buying multiple spools to take advantage of volume pricing and ensure consistent material properties across projects. The material's reliability makes it suitable for production applications where consistency matters.

For educational purposes, this filament provides an excellent introduction to engineering materials without the extreme cost of specialty filaments. Students can learn proper printing techniques for advanced materials while creating projects that demonstrate real mechanical principles.

view the special offer on multiple spoolsYou'll need a printer with an all-metal hotend capable of reaching 260°C. Most modern printers above the entry-level category meet these requirements.

Store in a sealed container with desiccant. While it has better moisture resistance than some nylons, proper storage extends its shelf life and print quality.

Yes, but warping can be an issue. Use an enclosed printer or draft shield for large prints, and ensure good bed adhesion.

While nylon is generally food safe, 3D printed parts have layer lines that can harbor bacteria. For food applications, use a food-safe coating after printing.

PA12 has better impact resistance while carbon fiber reinforced materials have higher stiffness. Choose based on your application needs.

It can be sanded, drilled, tapped, and finished like other nylons. It also accepts dyes well for coloring finished parts.

Join 73 satisfied professionals who have upgraded their 3D printing capabilities with eSUN PA12 filament. The current 30% discount won't last forever—this is the perfect time to invest in professional-grade printing materials.

Price increases to $100.99 after promotion ends. Limited stock available.

Get Your Discount Now

Complete review of Creality Chamber Heater: 70℃ temperature control, reduces warping, filament drying, dual safety protection. Perfect for ABS, PA, PC printing materials.

Comprehensive review of Anycubic's 10kg 405nm Standard Resin. Perfect balance of precision, affordability & reliability for Photon 3D printers. 64% discount available.

Complete review of 10kg PETG filament bundle: 50% discount, 5-star rated, perfect for hobbyists & professionals. Water-resistant, durable 3D printing material.