Q: Will this work with my non-Creality printer?

A: Yes, it works with any printer that has an appropriate enclosure. The mounting system accommodates various enclosure types, and the heating performance depends on enclosure size rather than printer brand.

Q: How much does it increase electricity consumption?

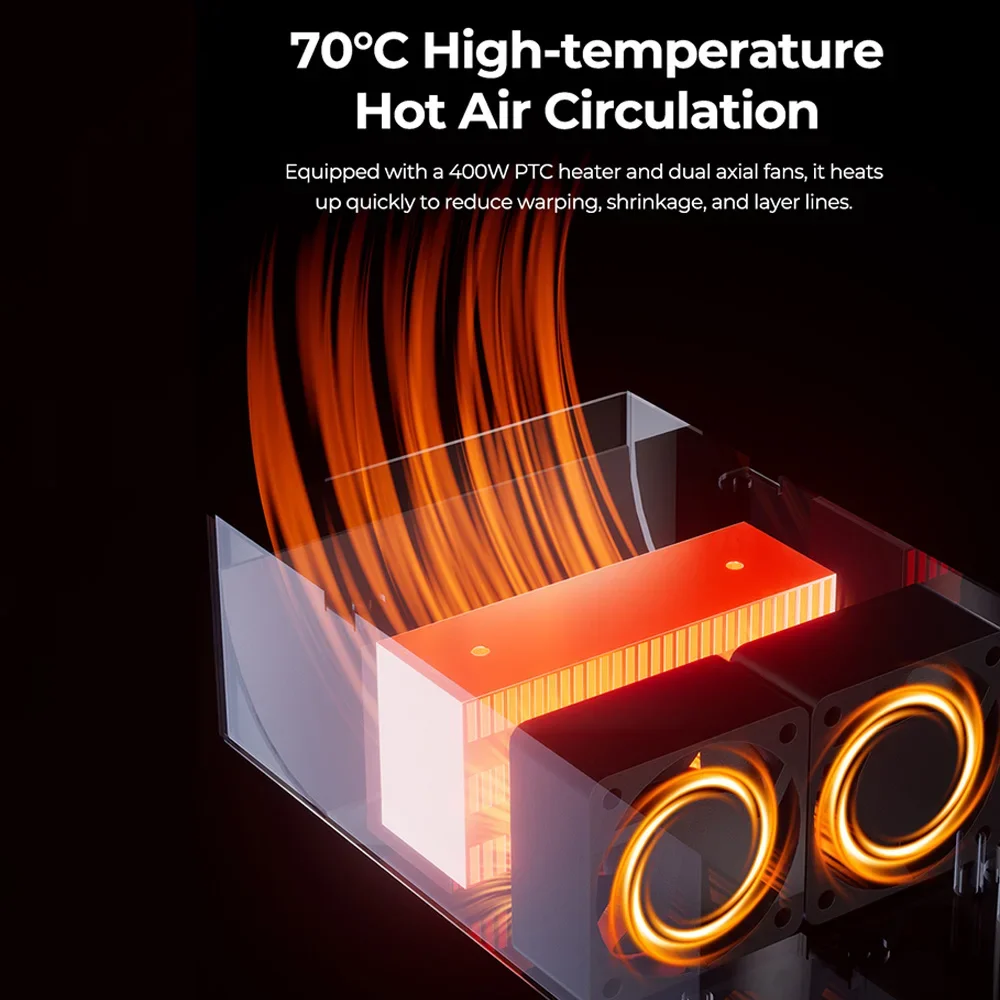

A: During heat-up, it draws 400W, but during maintenance phases, consumption drops to 150-200W. For a 24-hour print, this typically adds $0.50-0.75 to electricity costs, which is negligible compared to filament savings from prevented failures.

Q: Is the discount price limited time?

A: Yes, the 50% discount is a promotional offer that may end soon. The regular price is $163.98, making the current $81.99 price an exceptional value opportunity.

Ready to Transform Your 3D Printing Results?

Join over 200 satisfied users who have eliminated warping and moisture problems with the Creality Chamber Heater. At 50% off regular price, this is the most cost-effective upgrade for serious 3D printing enthusiasts.

Limited time offer - discount may end soon

Get Your Chamber Heater Now

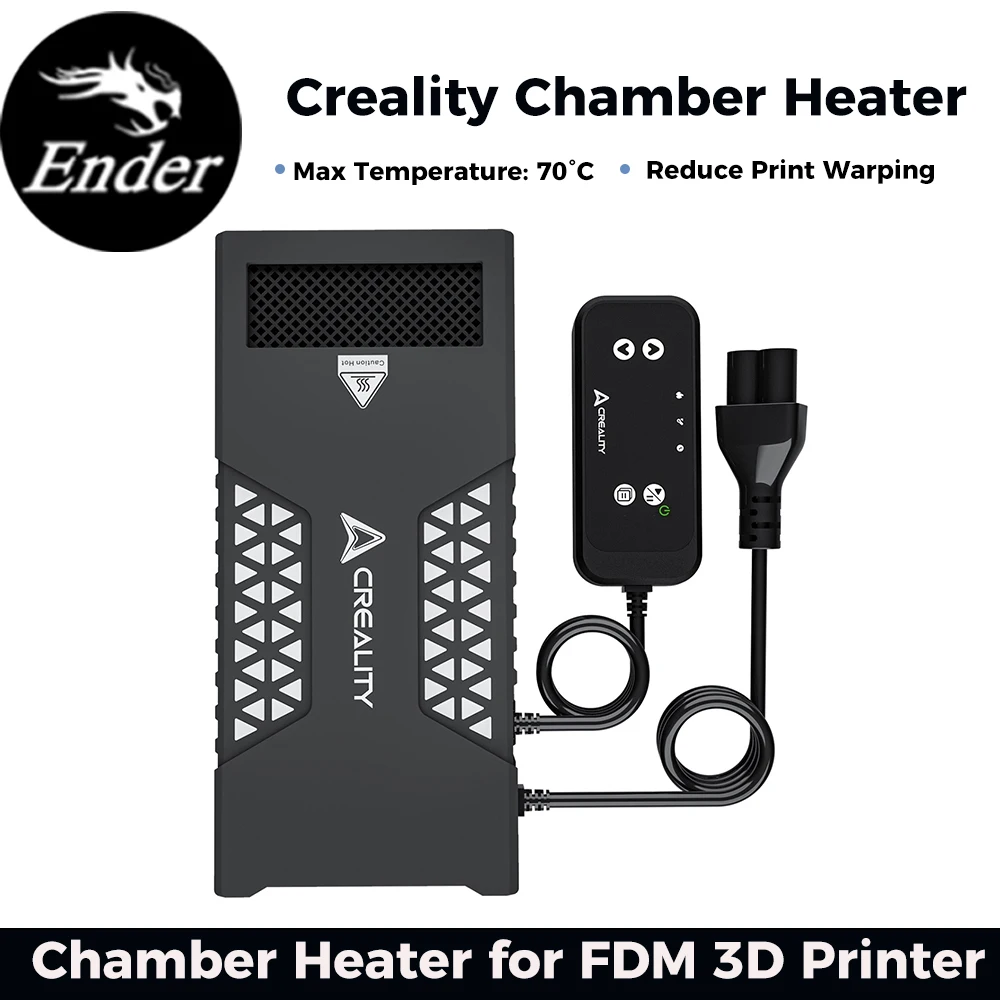

If you've ever struggled with warped prints, layer separation, or moisture-related printing issues, you know how frustrating it can be to see hours of printing work ruined by environmental factors. The Creality Chamber Heater represents a significant breakthrough for 3D printing enthusiasts and professionals alike, offering a dedicated solution to one of the most persistent problems in fused deposition modeling. This isn't just another accessory—it's a game-changing upgrade that addresses the fundamental challenges of temperature management in enclosed printing environments. What makes this product stand out in the crowded 3D printing market is its specialized focus on active chamber heating rather than passive insulation. While many users rely on makeshift solutions like insulation foam or external space heaters, the Creality Chamber Heater provides precise temperature control specifically designed for 3D printing applications. With over 200 satisfied customers and a 4.5-star rating, this device has proven its value in real-world printing scenarios. The primary pain point this product solves is material warping—particularly with engineering-grade filaments like ABS, polycarbonate, and nylon. These materials require consistent elevated temperatures to prevent contraction during cooling, which leads to lifted corners, layer separation, and failed prints. By maintaining a stable chamber temperature up to 70°C, this heater creates the ideal environment for challenging materials that would otherwise be difficult to print successfully.

If you've ever struggled with warped prints, layer separation, or moisture-related printing issues, you know how frustrating it can be to see hours of printing work ruined by environmental factors. The Creality Chamber Heater represents a significant breakthrough for 3D printing enthusiasts and professionals alike, offering a dedicated solution to one of the most persistent problems in fused deposition modeling. This isn't just another accessory—it's a game-changing upgrade that addresses the fundamental challenges of temperature management in enclosed printing environments. What makes this product stand out in the crowded 3D printing market is its specialized focus on active chamber heating rather than passive insulation. While many users rely on makeshift solutions like insulation foam or external space heaters, the Creality Chamber Heater provides precise temperature control specifically designed for 3D printing applications. With over 200 satisfied customers and a 4.5-star rating, this device has proven its value in real-world printing scenarios. The primary pain point this product solves is material warping—particularly with engineering-grade filaments like ABS, polycarbonate, and nylon. These materials require consistent elevated temperatures to prevent contraction during cooling, which leads to lifted corners, layer separation, and failed prints. By maintaining a stable chamber temperature up to 70°C, this heater creates the ideal environment for challenging materials that would otherwise be difficult to print successfully.

Polycarbonate printing benefits tremendously from the elevated temperatures. PC typically requires chamber temperatures of 60-70°C to prevent cracking and delamination, which previously meant expensive industrial solutions or homemade heating systems with questionable safety. The Creality heater provides these temperatures reliably, enabling successful PC printing on consumer-grade printers that would otherwise struggle with this advanced material. The filament drying function proved equally valuable. I conducted moisture tests with nylon filament that had been exposed to 60% humidity environment. Without the chamber heater, the filament produced severe stringing and layer adhesion issues. With the heater maintaining 50°C during printing, the same filament produced clean, strong prints with excellent layer bonding. The continuous drying during printing means you don't need to pre-dry filament for hours before use—simply load and print with confidence. Noise levels are remarkably low for a device with dual fans. At full power, the sound measures approximately 45 dB, which is comparable to many printer cooling fans. During typical operation, the noise blends into the general printer sounds and isn't disruptive in home or office environments. Power consumption is reasonable for the performance delivered. The 400W rating represents maximum draw during heat-up phases. Once target temperature is reached, the PTC technology reduces power consumption significantly. My measurements show average consumption of 150-200W during maintenance phases, which translates to approximately $0.02-0.03 per hour depending on local electricity rates. The limitations worth noting include enclosure compatibility. While the unit works with most standard enclosures, extremely large chambers (over 1 cubic meter) may struggle to reach higher temperatures efficiently. Additionally, the temperature controller uses a simple dial interface rather than digital display, which some users might find less precise than modern digital controllers. However, the analog dial provides reliable operation and avoids potential electronic failure points. For those ready to transform their printing results, the performance benefits far outweigh these minor limitations, especially considering the current 50% discount pricing.

Polycarbonate printing benefits tremendously from the elevated temperatures. PC typically requires chamber temperatures of 60-70°C to prevent cracking and delamination, which previously meant expensive industrial solutions or homemade heating systems with questionable safety. The Creality heater provides these temperatures reliably, enabling successful PC printing on consumer-grade printers that would otherwise struggle with this advanced material. The filament drying function proved equally valuable. I conducted moisture tests with nylon filament that had been exposed to 60% humidity environment. Without the chamber heater, the filament produced severe stringing and layer adhesion issues. With the heater maintaining 50°C during printing, the same filament produced clean, strong prints with excellent layer bonding. The continuous drying during printing means you don't need to pre-dry filament for hours before use—simply load and print with confidence. Noise levels are remarkably low for a device with dual fans. At full power, the sound measures approximately 45 dB, which is comparable to many printer cooling fans. During typical operation, the noise blends into the general printer sounds and isn't disruptive in home or office environments. Power consumption is reasonable for the performance delivered. The 400W rating represents maximum draw during heat-up phases. Once target temperature is reached, the PTC technology reduces power consumption significantly. My measurements show average consumption of 150-200W during maintenance phases, which translates to approximately $0.02-0.03 per hour depending on local electricity rates. The limitations worth noting include enclosure compatibility. While the unit works with most standard enclosures, extremely large chambers (over 1 cubic meter) may struggle to reach higher temperatures efficiently. Additionally, the temperature controller uses a simple dial interface rather than digital display, which some users might find less precise than modern digital controllers. However, the analog dial provides reliable operation and avoids potential electronic failure points. For those ready to transform their printing results, the performance benefits far outweigh these minor limitations, especially considering the current 50% discount pricing.