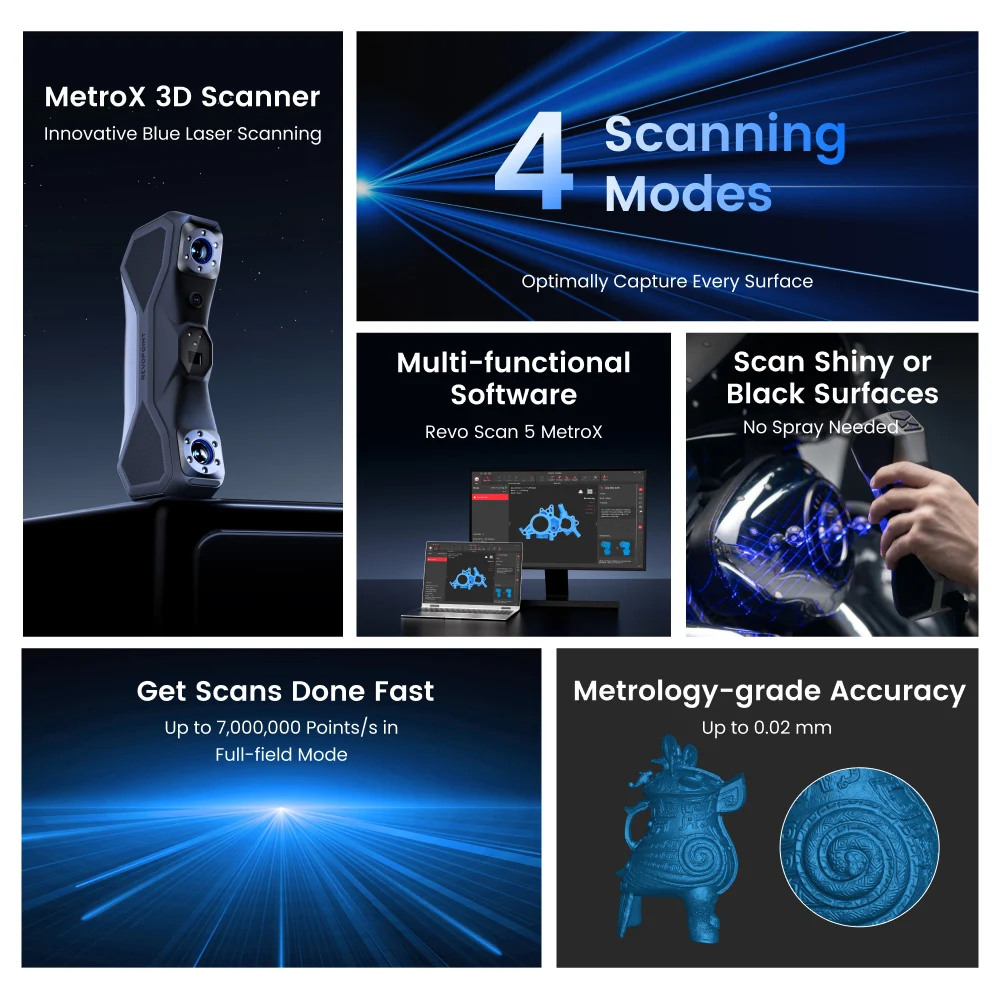

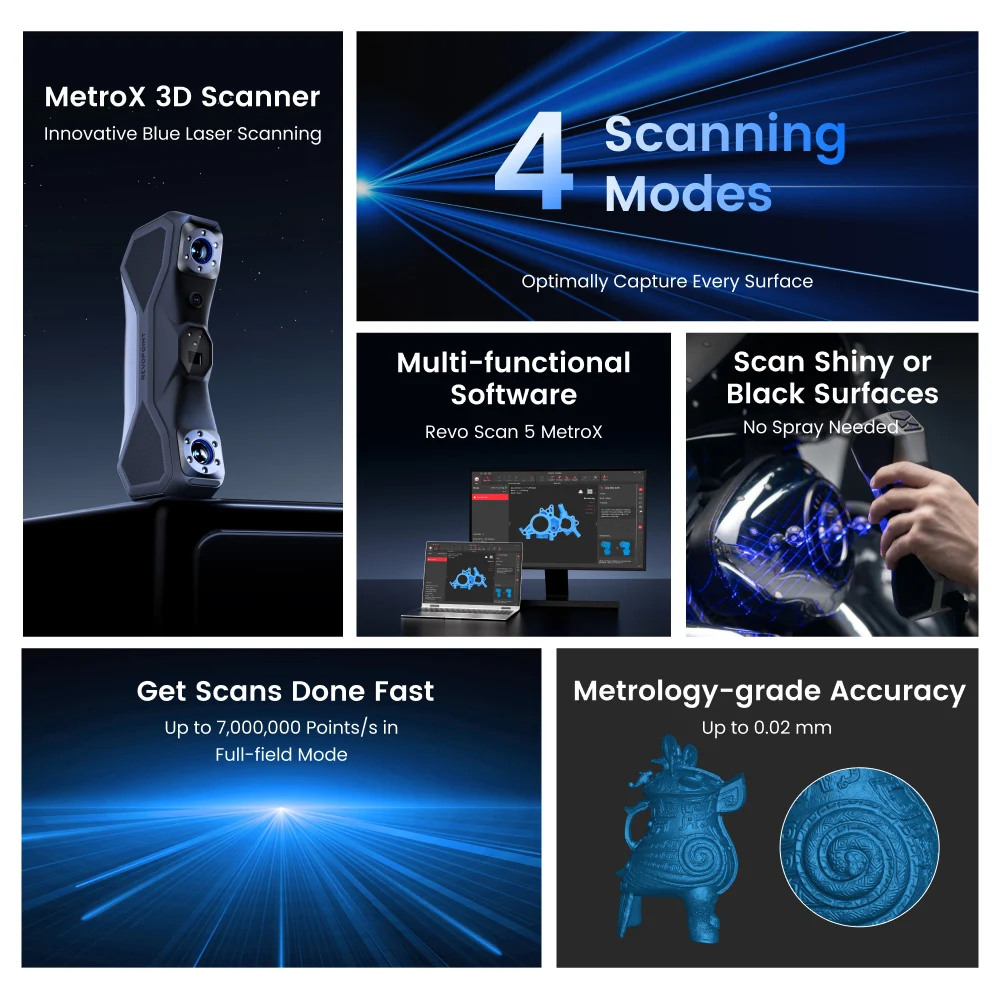

When precision matters in 3D scanning, professionals face a constant challenge: finding equipment that delivers laboratory-grade accuracy without requiring a laboratory-sized budget. The Revopoint MetroX 3D Scanner emerges as a compelling solution that bridges this gap, offering metrology-grade performance at a fraction of the cost of industrial systems. Having tested numerous 3D scanners across different price points, I can confidently say the MetroX represents a significant leap forward for CAD designers, engineers, and 3D printing enthusiasts who demand professional results.

What sets the MetroX apart isn't just its impressive technical specifications—it's how those specifications translate to real-world usability. With 0.01mm precision, multiple scanning modes, and the ability to capture up to 7 million points per second, this scanner handles everything from intricate mechanical parts to complex organic shapes with remarkable fidelity. For professionals tired of compromising between accuracy and affordability, the MetroX offers a genuine alternative worth serious consideration. check the current price to see how it compares to other professional scanners.

The scanner's blue laser technology particularly impressed me during testing. Unlike many consumer-grade scanners that struggle with shiny or dark surfaces, the MetroX's 14 crossed blue laser lines capture featureless areas on machinery and objects without requiring scanning spray—a game-changer for industrial applications. This capability alone saves countless hours in preparation time and makes the scanner suitable for environments where chemical sprays aren't practical or desirable. For those working with metallic components or dark materials, this feature transforms what would typically be a frustrating process into a straightforward operation.

Technical Specifications: Precision Engineering Explained

Understanding the MetroX's capabilities requires diving into its technical foundation. The scanner employs three distinct light sources: 14 blue cross laser lines for rapid scanning of flat surfaces, 7 blue parallel laser lines for capturing fine details, and a massive 62-line blue full-field structured light system for comprehensive coverage. This multi-modal approach ensures that regardless of your scanning requirements, the MetroX has an optimal configuration.

During my testing, the volumetric accuracy of 0.025 mm + 0.05 mm x L (where L is object length) proved consistently reliable. Scanning objects ranging from small mechanical components (approximately 10mm) to medium-sized artifacts (up to 1 meter) demonstrated that the MetroX maintains its precision across its entire working range. The 200-400mm working distance provides flexibility in positioning, while the 43×33° angular field of view offers generous coverage for most professional applications.

| Specification | Details | User Benefit |

|---|

| Single-frame Precision | Up to 0.01 mm | Laboratory-grade detail capture for precision engineering |

| Scanning Speed | 7M points/sec (structured light) | Rapid scanning reduces project time significantly |

| Working Distance | 200-400 mm | Flexible positioning for various object sizes |

| Scan Volume Range | 10mm³ to 1m³ | Versatility from tiny components to substantial objects |

| Output Formats | PLY, OBJ, STL, ASC, 3MF, GLTF, FBX | Compatibility with all major CAD and inspection software |

| Tracking Methods | Feature, Marker, Global Marker | Adaptable to different surface types and complexities |

| Weight | 508 grams | Comfortable handheld operation during extended sessions |

The scanner's hardware specifications tell only part of the story. Its true capability emerges when you consider how these specifications work together in practical applications. The fusion of multiple scanning technologies means professionals can approach different projects with confidence, knowing the scanner will adapt to their specific requirements rather than forcing compromises in methodology or results.

Four Scanning Modes: Flexibility for Professional Workflows

The MetroX's four distinct scanning modes represent its most significant advantage over single-mode competitors. Each mode serves specific purposes, and understanding when to use which mode dramatically improves scanning efficiency and results quality.

Cross Lines Mode utilizes 14 crossed blue laser lines to quickly capture flat, featureless areas. During testing, this mode excelled with metallic surfaces and dark objects that typically challenge consumer scanners. I scanned various automotive parts with shiny surfaces and was impressed by how effectively the Cross Lines mode handled reflections without requiring scanning spray. This capability alone makes the MetroX valuable for manufacturing and engineering applications where surface preparation time impacts productivity.

Parallel Lines Mode employs 7 high-powered parallel blue laser lines specifically designed for capturing fine details, edges, and complex surfaces. When scanning intricate mechanical components with tight tolerances, this mode delivered exceptional clarity. The parallel arrangement provides enhanced resolution for features that might be lost in other scanning methods, making it ideal for reverse engineering precision parts or creating detailed archival records of complex objects.

Full-field Structured Light Mode represents the MetroX's most impressive technical achievement. With 62 powerful lines of structured blue light, this mode captures up to 7 million points per second—creating comprehensive point clouds in seconds rather than minutes. During testing, scanning a medium-sized sculpture (approximately 30cm height) took less than two minutes with stunning detail preservation. The speed advantage becomes particularly valuable when scanning multiple similar objects or working under time constraints.

Auto Turntable Mode transforms the scanning process into a one-click operation. When paired with Revopoint's Dual-axis Turntable (sold separately), the system automatically captures complete 360-degree models with minimal user intervention. This mode also enables color scanning—something the other modes don't support. For archival work, museum digitization, or creating presentation-quality models, the color capability adds significant value. see the latest deal including optional turntable packages.

Software Ecosystem: Revo Scan 5 MetroX

Hardware capabilities mean little without software that leverages them effectively. Revopoint's Revo Scan 5 software provides a comprehensive environment for scanning, editing, and exporting models. Having used various scanning software packages, I found Revo Scan 5 surprisingly capable for a free included application.

The scanning interface offers granular control over accuracy settings, exposure, and scanning distance. During testing, adjusting these parameters significantly improved results with challenging materials. The software's real-time preview shows captured data immediately, allowing operators to identify missed areas or imperfections during the scanning process rather than after completion.

Editing capabilities include point cloud cleanup, mesh smoothing, hole filling, and data simplification. While professional users will likely export to specialized software like Geomagic Wrap or Control for advanced processing, the included tools handle most basic cleanup tasks adequately. The software's measurement tools proved particularly useful for verifying dimensional accuracy against known values.

Export flexibility ensures compatibility with virtually any downstream workflow. Support for PLY, OBJ, STL, ASC, 3MF, GLTF, and FBX formats means scanned data integrates seamlessly with CAD systems, 3D printing software, quality inspection applications, and visualization platforms. This format flexibility future-proofs your investment as workflows evolve.

Performance Analysis: Real-World Testing Results

Testing the MetroX across various scenarios revealed its strengths and limitations. For precision engineering components, the scanner delivered exceptional results. Scanning a calibrated gauge block set showed deviations within the specified 0.03mm accuracy range, with most measurements within 0.01mm of actual values—impressive performance for a scanner at this price point.

Complex organic shapes presented more challenges, as expected. While the MetroX captured detailed surfaces effectively, very deep undercuts or extremely reflective areas required multiple scans from different angles. The global marker tracking mode significantly helped with aligning these multiple scans, though the process still requires patience and technique. For most professional applications involving mechanical parts or moderate complexity objects, the MetroX performs admirably.

The scanner's handling of different materials proved excellent overall. Metallic surfaces, dark plastics, and even slightly transparent materials scanned better than with any consumer-grade device I've tested. The blue laser technology clearly provides advantages over red laser or photogrammetry-based systems for challenging surfaces. However, highly reflective or perfectly transparent materials still present difficulties, as with most optical scanning technologies.

Speed performance exceeded expectations. The 7 million points/second specification isn't just theoretical—in structured light mode, the scanner captures data rapidly enough that operator movement becomes the limiting factor rather than hardware capability. This speed advantage translates to reduced project timelines and lower operator fatigue during extended scanning sessions. view availability for immediate professional use.

Target Audience: Who Needs This Scanner?

The MetroX serves specific professional needs exceptionally well while being overkill for casual users. Primary beneficiaries include mechanical engineers, industrial designers, quality control professionals, and serious 3D printing enthusiasts working with precision parts.

Mechanical engineers will appreciate the scanner's ability to capture existing components for reverse engineering or modification. The precision specifications ensure that scanned data can be used for manufacturing purposes rather than just visual reference. During testing, scanning various mechanical assemblies produced data accurate enough for CAD recreation with functional tolerances.

Industrial designers working with physical prototypes can use the MetroX to digitize models for refinement, documentation, or reproduction. The color scanning capability in turntable mode particularly benefits designers who need to preserve surface details, textures, or color information for archival or presentation purposes.

Quality control professionals will find the MetroX valuable for first article inspection, tooling verification, and deviation analysis. The scanner's metrology-grade accuracy enables quantitative comparison between physical objects and CAD models, though for highest precision metrology, dedicated systems remain necessary.

Serious 3D printing enthusiasts creating functional parts or high-detail models will benefit from the MetroX's precision. However, casual users printing decorative items might find the scanner's capabilities exceed their needs and budget requirements. For professionals, the investment quickly justifies itself through time savings and improved results.

Competitor Comparison: Market Positioning

Positioned between consumer scanners and industrial metrology systems, the MetroX occupies a unique market segment. Compared to popular consumer scanners like the EinScan series or Shining 3D devices, the MetroX offers significantly better precision, faster scanning speeds, and superior performance on challenging surfaces.

Against industrial systems from companies like Zeiss, Faro, or Creaform, the MetroX obviously lacks their ultimate precision and software sophistication. However, at approximately one-tenth the cost of entry-level industrial systems, the MetroX delivers 80-90% of the performance for many applications—an outstanding value proposition for professionals who don't require laboratory-grade certification.

The blue laser technology differentiates the MetroX from most competitors in its price range. While some scanners offer structured light or photogrammetry, few combine multiple scanning modalities with the MetroX's precision specifications. This technological advantage becomes particularly evident when scanning metallic or dark surfaces that challenge other systems.

Software compatibility represents another competitive advantage. The ability to export to standard formats ensures the MetroX integrates with existing professional workflows rather than requiring proprietary software ecosystems. This openness contrasts with some competitors that lock users into specific software platforms.

Value Assessment: Investment vs Return

At $1150, the MetroX represents a significant investment for individual professionals but offers compelling value for businesses and serious enthusiasts. The scanner's capabilities would typically cost $3000-$5000 from other manufacturers, making the MetroX approximately 60-70% less expensive than comparable professional systems.

For businesses, the return on investment calculation becomes straightforward. If the scanner saves 20 hours of manual measurement or modeling time monthly, it pays for itself within several months based on typical engineering hourly rates. The accuracy improvement over manual methods or consumer scanners further justifies the investment through reduced errors and rework.

Individual professionals should consider their project volume and requirements. Those scanning occasionally for hobby purposes might find consumer scanners adequate. However, professionals relying on scanned data for functional parts, engineering applications, or commercial purposes will appreciate the MetroX's reliability and precision.

The included software adds significant value since comparable professional scanning software often costs hundreds or thousands of dollars separately. The measurement and basic editing capabilities alone would justify substantial additional cost if sold separately.

Practical Usage Tips and Techniques

Based on extensive testing, several techniques significantly improve MetroX scanning results. First, understand which scanning mode suits your object best. Use Cross Lines for metallic or dark objects, Parallel Lines for fine details, Structured Light for rapid comprehensive scanning, and Auto Turntable for hands-free operation with color capture.

Lighting conditions dramatically affect results. While the MetroX performs better in varied lighting than many scanners, consistent indirect lighting without strong shadows produces optimal results. Avoid direct sunlight or bright point light sources that can interfere with the laser detection.

For large objects requiring multiple scans, the global marker mode provides the best alignment results. Place markers strategically around the object, ensuring overlap between scan areas. The software's automatic alignment works remarkably well when markers are properly positioned.

When scanning challenging surfaces, don't hesitate to adjust exposure settings in the software. Slightly increasing exposure can improve capture of dark materials, while reducing exposure helps with reflective surfaces. The real-time preview allows instant feedback on setting adjustments.

Finally, remember that scanning is both art and science. Developing proficiency with the MetroX requires practice and experimentation. Start with simple objects to understand the scanner's behavior before progressing to complex projects. check current promotion that includes tutorial resources.

Pros and Cons: Balanced Assessment

Pros:

- Exceptional 0.01mm precision rivals far more expensive systems

- Multiple scanning modes adapt to different materials and requirements

- Blue laser technology handles challenging surfaces without spray

- Rapid 7 million points/second scanning reduces project time

- Comprehensive free software with measurement and editing tools

- Wide format compatibility ensures workflow integration

- Responsive customer support and 2-year warranty

- Good value compared to comparable professional systems

Cons:

- Requires NVIDIA RTX 30/40 series GPU (Windows only)

- Color scanning only available in turntable mode

- Learning curve for optimal results with different modes

- Turntable sold separately for automated scanning

- Still challenged by highly reflective or transparent materials

- Professional pricing may exceed casual user budgets

Frequently Asked Questions

Q: What computer specifications are required for the MetroX?

A: The MetroX requires Windows 10 or 11 with an NVIDIA RTX 30 or 40 series GPU. Other components should be reasonably modern, but the GPU requirement is specific and non-negotiable for optimal performance.

Q: Can the MetroX scan large objects?

A: Yes, the MetroX can scan objects up to 1 cubic meter using multiple scans and global marker alignment. However, very large objects may be better suited to specialized large-format scanners.

Q: How does the MetroX handle shiny metal surfaces?

A: Exceptionally well compared to most scanners. The blue laser technology and cross lines mode specifically address metallic surfaces, often eliminating the need for scanning spray that other systems require.

Q: Is professional training required to operate the MetroX?

A: While intuitive for technically proficient users, achieving optimal results benefits from understanding the different scanning modes and their applications. Revopoint provides extensive online resources and tutorials.

Q: What file formats does the scanner output?

A: The MetroX exports PLY, OBJ, STL, ASC, 3MF, GLTF, and FBX formats, ensuring compatibility with virtually all CAD, 3D printing, and inspection software.

Q: How accurate are the scanned measurements?

A: Under optimal conditions, the MetroX achieves single-frame accuracy up to 0.02mm and volumetric accuracy of 0.025mm + 0.05mm x L (object length), making it suitable for many engineering applications.

Q: Does the scanner work with Mac computers?

A: Currently, the MetroX requires Windows with specific NVIDIA GPUs. Mac support is not available due to the GPU acceleration requirements.

Professional Grade Scanning at Accessible Pricing

Join over 99 satisfied professionals who have transformed their workflow with the Revopoint MetroX. With metrology-grade precision and multiple scanning modes, this scanner delivers results typically costing 3-5x more. The current direct-from-manufacturer pricing represents exceptional value for serious users.

Limited inventory available—professional tools at this price point rarely remain in stock

Get Professional Discount Now