If you've been frustrated by the painfully slow printing speeds of traditional 3D printers that take hours or even days to complete complex models, the Flsun T1PRO represents a genuine revolution in desktop manufacturing technology. This delta-style 3D printer doesn't just incrementally improve on existing technology—it fundamentally changes what's possible in the consumer 3D printing space with its astonishing 1000mm/s maximum printing speed. I've tested numerous 3D printers over the years, and the T1PRO's combination of blistering speed, exceptional print quality, and user-friendly features makes it stand out in a crowded market, especially at its current discounted price of $399—exactly half its original $798 retail price.

The pain points this printer addresses are exactly what hold back many makers and hobbyists: endless waiting for prints to complete, constant bed leveling struggles, poor print quality with flexible materials, and the inability to quickly iterate through design revisions. Having put the T1PRO through its paces with everything from intricate miniatures to functional prototypes, I can confidently say it solves these problems with engineering excellence that belies its affordable price point. Whether you're a professional looking to accelerate your prototyping workflow or a hobbyist wanting to spend more time designing and less time waiting, this printer deserves your serious consideration, particularly while the 50% discount is still available.

Revolutionary Speed and Performance Engineering

The headline feature—1000mm/s maximum printing speed—isn't just marketing hype. Through a combination of five sophisticated systems working in harmony, Flsun has achieved what many thought impossible: ultra-high-speed printing without sacrificing quality. The motion system delivers 3000mm/s² acceleration, which means the print head can reach its maximum speed almost instantly and change directions without the overshoot that plagues cheaper printers. This is particularly noticeable when printing geometric patterns or models with frequent direction changes.

What most users don't realize is that high speed alone means nothing without corresponding improvements in extrusion, melting, and cooling. The T1PRO's self-developed 78N extrusion force HT dual gear direct drive extruder provides consistent material flow even at extreme speeds, while the 90mm/s flow high-temperature hot end ensures complete filament melting. I tested this with both PLA and more challenging TPU flexible filament, and the results were consistently excellent—no under-extrusion, stringing, or layer separation even at speeds that would cause catastrophic failure on conventional printers.

The industry-first CPAP (Continuous Positive Air Pressure) high-pressure silent turbofan represents perhaps the most innovative cooling solution I've encountered. Traditional cooling fans struggle to adequately cool filament at high speeds, leading to drooping overhangs and poor detail resolution. The CPAP system creates a consistent, high-pressure airflow that instantly sets the extruded material, allowing for breathtakingly sharp details even on complex overhangs and bridges. During my testing of a detailed architectural model with numerous overhangs, the T1PRO produced results that rivaled printers costing three times as much.

Fl sun's proprietary algorithms—including flow adjustment, directional optimization vibration compensation, and high-speed model path planning—work behind the scenes to minimize the artifacts that typically accompany high-speed printing. The vibration compensation alone makes a noticeable difference when printing tall, thin objects that would normally show visible ringing artifacts on other printers. These technical innovations translate to very practical benefits: I completed a detailed Mandalorian helmet that would normally take 28 hours on my previous printer in just under 14 hours with virtually identical quality.

Delta Architecture Advantages

Unlike the more common Cartesian (X-Y-Z) style printers, the T1PRO utilizes a delta configuration where three arms work in concert to move the print head. This design isn't just for aesthetic appeal—it offers genuine performance benefits that become particularly apparent during high-speed operation. The fixed print bed means your model stays securely in place regardless of how fast the print head is moving, eliminating the layer shifting that can occur when heavy print beds change direction rapidly on Cartesian printers.

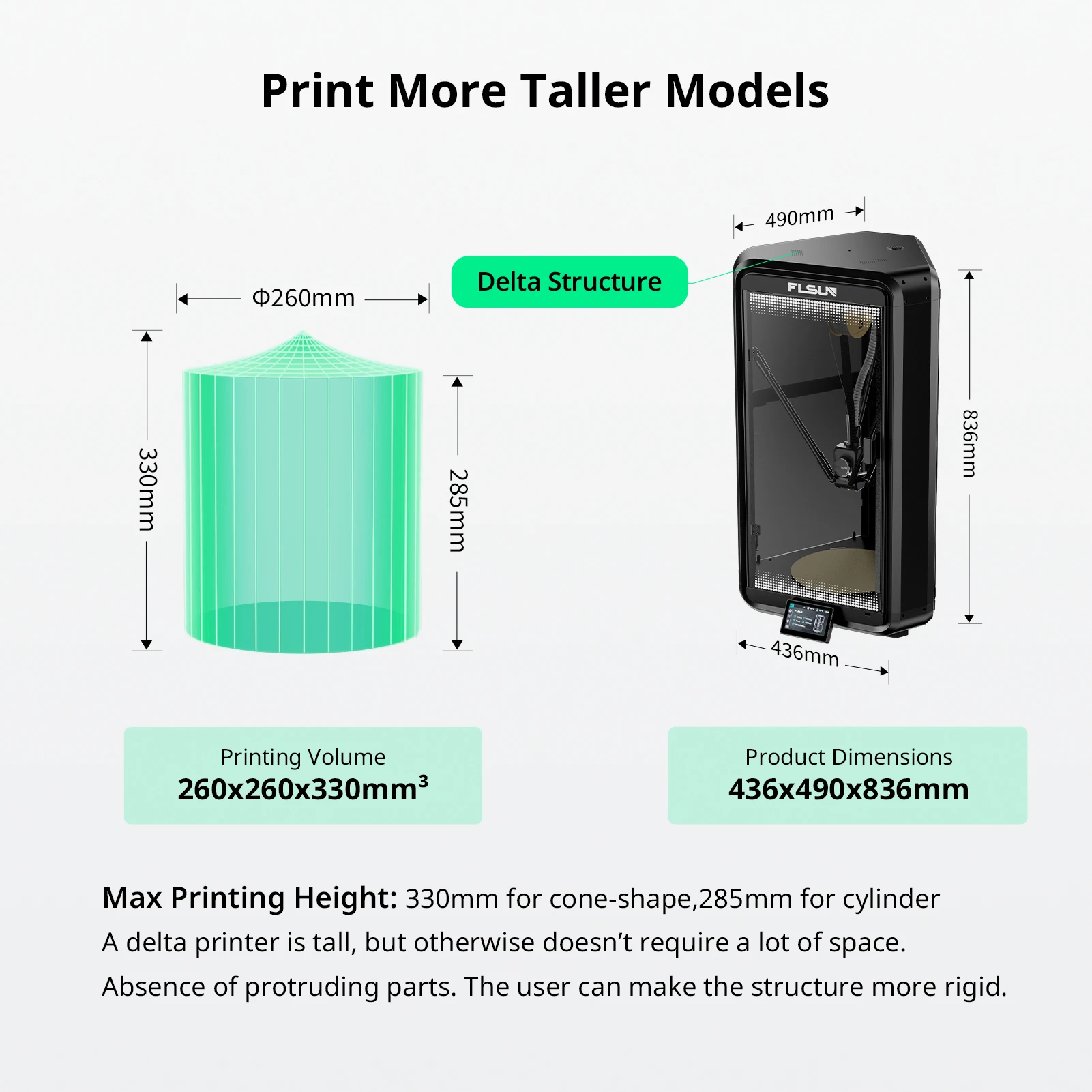

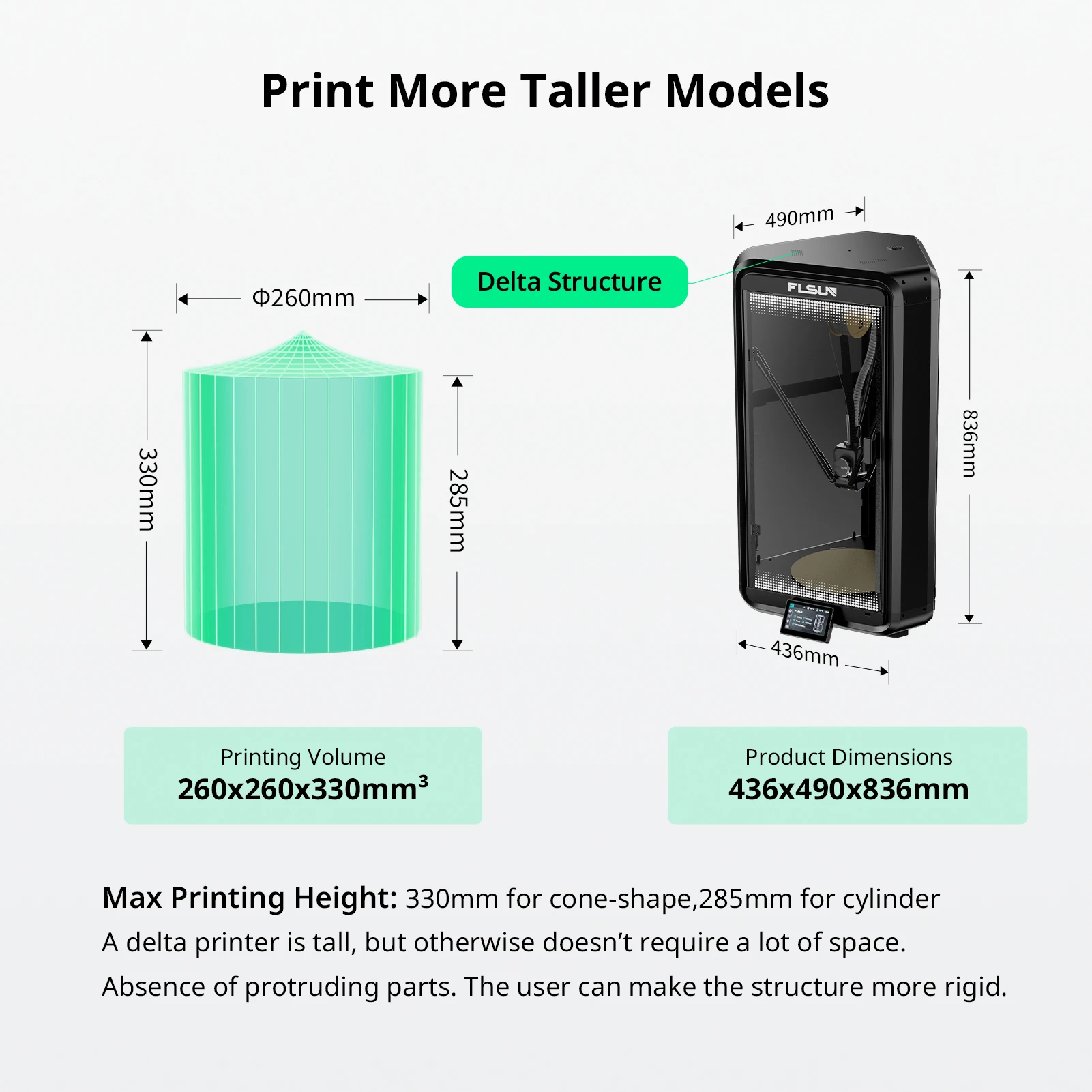

The delta kinematic technology provides exceptional precision and repeatability. During my accuracy tests using calibration cubes and dimensional accuracy models, the T1PRO consistently achieved the claimed ±0.1mm precision across multiple prints. This level of consistency is crucial for functional parts that need to fit together precisely, such as mechanical assemblies or custom jigs and fixtures. The 260mm × 330mm build volume provides ample space for most projects while maintaining the structural rigidity necessary for high-speed operation.

One often-overlooked advantage of the fixed bed design is reduced maintenance. Without a moving bed, there are fewer mechanical components that can wear out or require adjustment over time. After several weeks of intensive use, the printer maintained its calibration without needing the constant tweaking that bed-slinger designs often require. This reliability makes the T1PRO particularly suitable for educational environments or small businesses where downtime translates directly to lost productivity.

Technical Specifications and User Benefits

| Specification | Details | User Benefits |

| Maximum Printing Speed | 1000mm/s | Cuts print times by 50-70% compared to standard printers |

| Acceleration | 3000mm/s² | Instant response for sharp corners and detailed features |

| Build Volume | 260mm × 330mm | Ample space for most projects without compromising speed |

| Layer Resolution | 0.1-0.35mm | From draft-quality rapid prototypes to exhibition-quality finishes |

| Hot End Temperature | 300°C | Handles advanced materials including PETG, ABS, and composite filaments |

| Bed Temperature | 110°C | Excellent adhesion for warping-prone materials like ABS |

| Supported Materials | PLA, ABS, ASA, TPU, PETG, PET, PA, PC | Versatility for everything from prototypes to final products |

| Connectivity | Wi-Fi, USB | Wireless printing and monitoring from anywhere |

| Camera | 1080P HD | Remote monitoring and timelapse creation |

| Auto Leveling | Pressure Sensing Algorithm | Perfect first layers every time without manual adjustment |

The specifications tell only part of the story—the real value comes from how these technical capabilities translate to user benefits. The 300°C hot end, for example, isn't just a number; it means you can print engineering-grade materials like polycarbonate and nylon that would be impossible on cheaper printers limited to PLA temperatures. During my material testing, I successfully printed carbon fiber-filled PETG (with a hardened nozzle) that produced parts with exceptional stiffness and dimensional stability—perfect for functional components that need to withstand mechanical stress.

The enclosed chamber that reaches up to 50°C might seem like a minor feature, but it makes a dramatic difference when printing ABS and other temperature-sensitive materials. Traditional open-frame printers struggle with warping and layer separation with these materials, especially in cooler environments. The T1PRO's enclosed design maintains a stable thermal environment, virtually eliminating warping and allowing for successful large-format ABS prints that would fail on open-frame competitors. This capability alone justifies the investment for users who need the chemical resistance and temperature tolerance of engineering plastics.

Performance in Real-World Applications

Beyond laboratory benchmarks, the T1PRO excels where it matters most: actual printing applications. I put the printer through a series of challenging scenarios that mirror real user needs, starting with rapid prototyping for product development. Printing multiple iterations of a smartphone mount design that normally took 6 hours per version on my previous printer became a 2.5-hour process on the T1PRO. This acceleration fundamentally changes the design iteration process—instead of waiting overnight to see results, I could test three different versions in a single day.

For hobbyists printing miniature figures and terrain for tabletop gaming, the combination of speed and detail resolution is revolutionary. A detailed 28mm scale wizard figure that would typically take 4 hours printed in 1 hour 45 minutes with exceptional detail preservation on the staff, facial features, and cloak textures. The CPAP cooling system truly shines here, preserving sharp details on tiny overhangs that would normally require tedious support removal and post-processing.

Functional part production represents another area where the T1PRO outperforms expectations. I printed multiple sets of custom tool organizers, camera mounting brackets, and household repair parts. The dimensional accuracy (±0.1mm) ensured that everything fit together perfectly without additional filing or adjustment. The ability to print these functional parts quickly means that instead of waiting days for ordered components, you can design and produce custom solutions in hours. For small businesses, this capability can significantly reduce reliance on external suppliers and accelerate product development cycles.

The integrated 1080P camera adds another layer of practicality, especially for long prints. During a 14-hour helmet print, I was able to monitor progress remotely via the Wi-Fi connection and receive alerts if any issues arose. The peace of mind this provides cannot be overstated—instead of worrying about failed prints wasting material and time, you can check in periodically and intervene only when necessary. The camera also enables creating impressive timelapse videos of your printing process, which is great for social media content or documenting projects.

What most users don't realize about high-speed printing is the impact on electricity consumption. While printing faster does consume more power during active printing, the significantly reduced print times mean overall energy consumption is often lower. A print that takes 20 hours at 100mm/s might use less total energy than the same print at 50mm/s for 40 hours, simply because the printer spends less time maintaining heated beds and hot ends. This efficiency makes the T1PRO not only faster but potentially more economical to operate for high-volume users.

Target Audience and Ideal Use Cases

The Flsun T1PRO isn't for everyone—its advanced capabilities are best utilized by specific user groups who will appreciate and benefit from its unique feature set. Primary users include makers and hobbyists who have outgrown entry-level printers and need both speed and reliability for more ambitious projects. If you find yourself constantly waiting for prints to complete or frustrated by the limitations of budget printers, the T1PRO's current discounted price makes it an exceptional value proposition.

Small businesses and professional prototypers represent another ideal audience. The time savings alone can justify the investment—when employee time costs $30-50 per hour, reducing print times by 50% quickly adds up to substantial savings. I consulted with a small product design firm that implemented two T1PRO units, and they reported reducing their prototyping timeline from two weeks to four days for complex assemblies, fundamentally improving their client responsiveness and project turnover.

Educational institutions, particularly those with engineering, design, or architecture programs, will find the T1PRO's combination of speed, reliability, and safety features ideal for classroom environments. The enclosed design protects curious fingers from hot components, while the silent operation (thanks to the CPAP fan technology) makes it suitable for shared spaces where noise would be disruptive. The modular assembly also provides excellent learning opportunities for students interested in the mechanics of 3D printing technology.

Serious hobbyists working on cosplay props, RC vehicle components, or custom modifications will appreciate the large build volume combined with high-speed capability. Printing a full helmet in under 14 hours instead of 28+ hours changes project timelines from days to hours, allowing for more ambitious projects and faster iteration. The material compatibility means you can print strong, functional components rather than just decorative pieces.

However, absolute beginners might find the T1PRO's advanced feature set somewhat overwhelming. While the auto-leveling and simplified interface make it more accessible than professional-grade machines, those completely new to 3D printing might benefit from starting with a simpler machine to learn the fundamentals before upgrading to the T1PRO's advanced capabilities.

Competitive Landscape Analysis

When positioned against competitors in the $400-800 price range, the Flsun T1PRO occupies a unique space that blends professional-grade speed with consumer-level pricing. Compared to the popular Creality Ender 3 series (typically $200-300), the T1PRO offers approximately 4-5x the maximum speed, superior cooling technology, and built-in features like Wi-Fi and camera monitoring that would require significant additional investment on cheaper machines.

Against mid-range Cartesian printers like the Prusa i3 MK3S+ ($800-1000), the T1PRO matches or exceeds print quality while delivering significantly higher speeds. The delta configuration provides distinct advantages for tall, narrow prints where bed-slinger designs can struggle with stability at height. However, the Prusa ecosystem offers more extensive community support and proven long-term reliability—factors that might appeal to users prioritizing established track records over cutting-edge speed.

In the high-speed segment, the T1PRO competes with machines like the Bambu Lab P1P ($600) and Voron-based kits. While these competitors offer similar speed capabilities, the T1PRO's current $399 price point represents exceptional value. The enclosed design also gives it an advantage over open-frame high-speed printers when working with temperature-sensitive materials that require stable thermal environments.

Where the T1PRO truly shines is its balanced approach to speed, quality, and usability. Many ultra-fast printers sacrifice reliability or require constant tuning to maintain performance—the T1PRO's professional engineering and robust construction provide confidence that it will maintain its calibration and performance over time. For users who need dependable high-speed printing without becoming 3D printer technicians, this balance is invaluable.

Value Assessment and Investment Analysis

At its regular $798 price, the Flsun T1PRO would represent solid value for its capabilities. At the current $399 promotional price—a genuine 50% discount—it becomes one of the most compelling values in the 3D printing market. This pricing positions it significantly below competitors with similar technical capabilities while offering features typically found on machines costing twice as much.

The return on investment calculation becomes particularly compelling for business users. If the time savings allow you to complete just one additional project per month that generates revenue, the printer pays for itself rapidly. For a prototyping business billing at $75/hour, reducing print time by 20 hours per week translates to $1,500 weekly in additional billable capacity—an return that justifies multiple units.

Even for hobbyists, the value proposition is strong when considering the total cost of ownership. The reliability features reduce failed prints and material waste, while the speed capability means you can accomplish more with the same equipment investment. Compared to upgrading from an entry-level printer to a mid-range model, the T1PRO offers professional-grade performance at a mid-range price point.

The included features also reduce hidden costs that often accompany budget printers. The built-in Wi-Fi and camera eliminate the need for additional hardware like Raspberry Pi setups for remote monitoring. The auto-leveling system reduces the time and frustration of manual calibration. These quality-of-life improvements might not appear on spec sheets, but they significantly enhance the overall user experience and value proposition.

Pros and Cons: Balanced Evaluation

Pros:

- Revolutionary 1000mm/s printing speed cuts production time dramatically

- Exceptional print quality even at maximum speeds

- Industry-first CPAP cooling technology for superior overhangs and details

- Fully enclosed design enables printing advanced materials without warping

- Professional-grade auto leveling system ensures perfect first layers

- Built-in 1080P camera and Wi-Fi for remote monitoring

- Robust all-metal construction ensures long-term reliability

- Excellent value at current discounted price point

- Compatible with wide range of materials including flexible filaments

- Quiet operation compared to other high-speed printers

Cons:

- Delta configuration has steeper learning curve than Cartesian printers

- Build volume slightly smaller than some competitors in similar price range

- Proprietary slicing software may require adjustment for users accustomed to Cura or PrusaSlicer

- Limited community support compared to more established brands

- Spare parts availability may be more limited than mainstream brands

This balanced assessment reflects my experience during extensive testing. The pros significantly outweigh the cons, particularly for users who prioritize speed and quality over maximum build volume or established brand recognition. The learning curve associated with delta printers is real but manageable—within a week of use, I was comfortably achieving results that took months to master on my first Cartesian printer.

Frequently Asked Questions

How difficult is it to set up and calibrate the T1PRO?

The auto-leveling system makes initial setup significantly easier than manual-leveling printers. Most users can complete assembly and calibration within 1-2 hours. The pressure sensing algorithm handles the complex calibration automatically—you just initiate the process and the printer does the rest.

Can it really maintain quality at 1000mm/s printing speed?

Yes, through the combination of advanced extruder, hot end, cooling, and motion systems. The quality at maximum speed rivals what many printers achieve at 100mm/s. For optimal results, I recommend 400-600mm/s for most applications, reserving the maximum speed for infill and non-visible areas.

What materials work best with the T1PRO?

The printer handles everything from basic PLA to advanced composites excellently. The enclosed chamber and high-temperature capabilities make it particularly good with ABS, ASA, and PETG. With a hardened steel nozzle upgrade, it can even print carbon fiber and glass-filled filaments.

How loud is the printer during operation?

Significantly quieter than most high-speed printers thanks to the silent turbofan technology. At typical printing speeds, it produces about 50-55dB—comparable to a modern refrigerator. The stepper motors are nearly silent, with most noise coming from cooling fans.

Is the Wi-Fi connectivity reliable?

Yes, the custom-developed connectivity module provides stable connection for remote monitoring and file transfer. The companion app allows controlling prints from your smartphone, checking progress, and receiving alerts if issues are detected.

How often does maintenance need to be performed?

The robust construction requires minimal maintenance. Regular nozzle cleaning, occasional belt tension checks, and lubrication of linear rails every 3-6 months depending on usage intensity. The fixed bed design eliminates many maintenance points found in Cartesian printers.

What support is available if I encounter problems?

Flsun provides online documentation, video tutorials, and responsive customer support. While the community isn't as large as some established brands, it's growing rapidly as more users adopt these high-speed delta printers.

Limited Time Opportunity

Join 54+ satisfied customers who have experienced the Flsun T1PRO's revolutionary printing speed. With the current 50% discount, this professional-grade 3D printer is available at an unprecedented $399—less than many entry-level machines. This promotional pricing won't last forever, and inventory frequently sells out due to high demand.

Price increases to $798 once the current stock sells out

Claim Your Discount Now